Technology

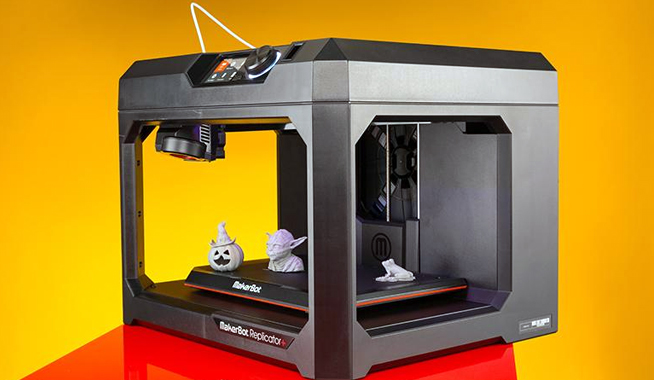

3D Printers and 4 ways they may change the world

Seemed like it was just yesterday when 3D printers were the talk of the town, hyped to the maximum, the next big thing, a technological wonder that was poised to revolutionize our world like never before. However, the fire seems to have burned out pretty quickly as most now think that these 3D printers are only suitable for printing miniature action figures for geeks.

Yes, its is known that these machines can do a lot more than just print action figures, but do their boons far outweigh their bane. Here are some talking points on potential harmful consequences of using 3D printers:

1) Energy-Hogging – They consume about 100 times more energy to melt plastic and mold it than injection molding.

2) Air Emission – The emission of unhealthy toxins from burning of plastics resulting in environmental issues and health risks.

3) Plastic Reliance – When the world is moving towards a plastic free age, ironically, the devices is centered around the usage of plastic for printing purposes.

4) Manufacturing Impact – Introduction of these printers in the car or aviation manufacturing industries to replace the human element will result in loss of jobs for manual labor.

For every bad thing that can be said about anything, there can definitely be a good thing that can be said about it too. Let us see how 3D printers can help change the world for the better.

Changing the way rhinos are being poached:-

A San Francisco-based startup has come up with an interesting concept to curb the poaching of rhino horns. Coupling the usage of 3D printers and the advancements in biotechnology, they are attempting to fabricate rhino horns from not synthetic materials but organic matter, metals, minerals, proteins and in cases even actual rhino DNA. The idea is to sell these artificial rhino horns to the said poachers ( to cover the cost of printing it ) who then go on to sell them in various international markets to make money and feed their families. This way, the rhinos are left unharmed and the market eventually dies out.

Tracking poachers using turtle egg shells:-

Not as big as a rhino but just as endangered, turtles have a huge market for their goods. Turtle eggs are stolen and sold for huge money with one egg going for a whopping $150. Paso Pacifico, an environmental conservation organization has taken the initiative to safeguard these turtle eggs from being poached and sold. They proposed to use 3D printers to print fake eggs, equip them with GSM and mixing them with the real eggs so as to enable the authorities to track their movement and uncover the sellers and their markets.

Medicine and health care:-

While we are on the topic of turtles and their safety, here’s another usage of the 3D printer, that is soon to be adopted by almost all veterinary hospitals around the world.

The image displayed below is of Akut-3 a loggerhead sea turtle that got struck on the jaw by a boat’s propeller. It was rescued by an organization called Dekamer.

A CT Scan of his skull showed what needed to be done, and BTech Innovations a company that specializes in custom implants created this printed beak and jaw made out of titanium for the wounded turtle. Now, Akut-3 is swimming freely deep in the ocean with his almost perfect printed jaw.

Self Service Dentistry:-

From turtles onto humans, we go on to the case of one Mr. Amos Dudley, a digital design student from New Jersey who decided to implement all that he learned about his own treatment. Choosing not to wear braces as a child left Amos with a crooked smile. Being broke but having unlimited access to all the high-end equipment from his lab at college, Amos decided to take things into his own hands.

Some cheap alginate powder that gave him a mold of his teeth along with a 3D laser scan that could translate imagery into existence which finally was fed into a 3D printer, he was able to print a model of his braces. At the cost of $60, he now has a fully functional set of bracers that are doing wonders for him. This is clearly an indication that 3D printing can be widely used in dentistry for treating the untreatable.

3D printers capable of outputting in colour and multiple materials already exist and will continue to improve to a point where functional products will be able to be output. With effects on energy use, waste reduction, customization, product availability, medicine, art, construction and sciences, 3D printing will change the manufacturing world as we know it.

Artificial Intelligence

UAE G42 Launches 8-Exaflop AI Supercomputer in India for Sovereign AI 2026

UAE-based G42 has announced plans to deploy an 8 exaflop AI supercomputer in India, announced at the AI Impact Summit 2026 in Delhi. This national-scale project partners with Cerebras, MBZUAI, and India’s C-DAC, operating under full Indian data sovereignty as part of the India AI Mission.

The supercomputer boosts sovereign AI capabilities, enabling startups, researchers, academics, SMEs, and government access for tailored applications like public services and language tech. G42 India CEO Manu Jain highlighted its role in making India AI-native while prioritizing security.

This follows India-UAE tech pacts in late 2025, positioning India among global leaders in exaflop AI infrastructure amid rising demand for localized compute. Cerebras CSO Andy Hock noted it will accelerate large model training for India-specific needs.

News

Google Launches Startup Hub in Hyderabad to Boost India’s Innovation Ecosystem

Google has launched the Google Startup Hub Hyderabad, a major step in strengthening India’s dynamic startup ecosystem. This new initiative aims to empower entrepreneurs, innovators, and developers by giving them access to Google’s global expertise, mentoring programs, and advanced cloud technology. The hub reflects Google’s mission to fuel India’s digital transformation and promote innovation through the Google for Startups program.

Located in the heart of one of India’s top tech cities, the Google Startup Hub in Hyderabad will host mentorship sessions, training workshops, and networking events designed for early-stage startups. Founders will receive Google Cloud credits, expert guidance in AI, product development, and business scaling, and opportunities to collaborate with Google’s global mentors and investors. This ecosystem aims to help Indian startups grow faster and compete globally.

With Hyderabad already home to tech giants like Google, Microsoft, and Amazon, the launch of the Google Startup Hub Hyderabad further cements the city’s position as a leading innovation and technology hub in India. Backed by a strong talent pool and robust infrastructure, this hub is set to become a growth engine for next-generation startups, driving innovation from India to global markets.

Technology

Jio Unveils Cloud PC Service to Bring Affordable Computing to Indian Households

- Jio Platforms has launched JioPC, a cloud-based virtual desktop service that transforms any television connected to a Jio Set Top Box into a fully functional computer.

- Users simply connect a keyboard and mouse to access a desktop-like environment, complete with web browsing, productivity tools, and educational apps—all without needing a physical PC or extra hardware.

- The service is device-agnostic and works with all consumer PC brands, making advanced computing accessible and affordable for millions across India.

JioPC is designed to support a wide range of activities, from professional work to online learning and creative projects. By leveraging Jio’s robust cloud infrastructure, users can run even compute-intensive AI applications directly from their TV screens. The platform also ensures data security and reliability, as all files and settings are safely stored in the cloud, protecting users from data loss even if their device is reset or replaced.

With JioPC, Jio aims to democratize digital access and bring high-performance computing to Indian households at a fraction of the traditional cost. The service supports popular productivity suites like LibreOffice and Microsoft Office online, and Jio is offering a free trial to encourage users to experience the benefits firsthand. This innovative move is set to reshape how people in India work, learn, and connect in the digital age.

Kwbqrsgq

May 27, 2025 at 12:55 am

Explore the ranked best online casinos of 2025. Compare bonuses, game selections, and trustworthiness of top platforms for secure and rewarding gameplaycrypto casino.

MichaelMof

July 12, 2025 at 5:33 am

[url=https://joyorganics.com/products/delta-9-thc-tincture-citrus ]delta 9 thc drops[/url] are a convenient and enjoyable way to win cannabidiol without the high. Numberless people consume them to affluence worry, improve zizz, or support complete wellness. The effects on the whole originate within 30–60 minutes and can model owing respective hours. You’ll find options with melatonin, vitamins, vegan ingredients, or no added sugar. They loosely transpire b emerge in a row of flavors and strengths. It’s most to start with a little quantity and often contain on the side of third-party lab testing to insure calibre and safety.

DannyJek

July 15, 2025 at 4:51 pm

https://joyorganics.com/products/organic-cbd-gummies are a advantageous and enjoyable temperament to run cannabidiol without the high. Assorted people abhor them to unaffectedness stress and strain, improve sleep, or support complete wellness. The effects generally speaking arise within 30–60 minutes and can model in compensation diverse hours. You’ll spot options with melatonin, vitamins, vegan ingredients, or no added sugar. They move in a range of flavors and strengths. It’s best to start with a critical dispense and every time confirm representing third-party lab testing to ensure grade and safety.

MM88

November 5, 2025 at 11:39 am

Khám phá thế giới giải trí trực tuyến đỉnh cao tại MM88, nơi mang đến những trải nghiệm cá cược thể thao và casino sống động.

GO88

November 5, 2025 at 5:38 pm

Tham gia cộng đồng game thủ tại Go88 để trải nghiệm các trò chơi bài, poker phổ biến nhất hiện nay.

谷歌站群

November 7, 2025 at 9:44 pm

专业构建与管理谷歌站群网络,助力品牌实现全域流量的强势增长。谷歌站群

ios超级签

November 13, 2025 at 1:53 pm

苹果签名,苹果超级签平台,ios超级签平台ios超级签苹果企业签,苹果超级签,稳定超级签名

J88

November 17, 2025 at 12:56 pm

Đến với J88, bạn sẽ được trải nghiệm dịch vụ cá cược chuyên nghiệp cùng hàng ngàn sự kiện khuyến mãi độc quyền.

MM88

November 20, 2025 at 2:13 am

Với giao diện mượt mà và ưu đãi hấp dẫn, MM88 là lựa chọn lý tưởng cho các tín đồ giải trí trực tuyến.

Kuwin

November 20, 2025 at 6:16 pm

kuwin sở hữu kho game đa dạng từ slot đến trò chơi bài đổi thưởng, mang đến cho bạn những giây phút giải trí tuyệt vời.

iwin

November 30, 2025 at 8:50 am

iwin – nền tảng game bài đổi thưởng uy tín, nơi bạn có thể thử vận may và tận hưởng nhiều tựa game hấp

greatwin casino auszahlung probleme

December 20, 2025 at 2:07 am

Stellen Sie einfach sicher, dass Sie ein Casino

wählen, das von der zuständigen Regulierungsbehörde lizenziert ist.

Wenn Sie Wert auf Krypto und schnelle Auszahlungen legen, ist

MegaPari sicherlich eines der besten Casinos für Sie. Speziell für Deutschland empfehlen wir zwei beste Online-Casinos, die sich von der Masse abheben.

Ein sicheres Online Casino schützt Ihre persönlichen und finanziellen Informationen mit den höchsten Standards und fordert nur

die erforderlichen Informationen an, ohne zusätzliche, unnötige Details für

Glücksspiele. Stellen Sie immer sicher, dass das von Ihnen gewählte Casino durch eine seriöse Behörde lizenziert wird,

um diese Risiken zu vermeiden. Nicht lizenzierte Casinos können aggressive Marketing Taktiken durchführen, was die

Spieler in die Irre führen kann, dass sie legitim sind.

In Deutschland ist es seit dem neuen Glücksspielgesetz nun nicht mehr möglich, in mehreren Casinos

verschiedener Anbieter parallel zu spielen. Wenn spielen zur Sucht wird, droht oft der finanzielle Abstieg, während man auf den großen Gewinn hofft.

Deshalb schreibt Stiftung Warentest, dass man lt. einem deutschen Rechtsanwalt gute Chancen hat,

für verlorenes Geld einen Ersatz zu erhalten.

References:

https://online-spielhallen.de/bizzo-casino-cashback-ihre-ruckerstattung-leicht-gemacht/

Royce Hotel Casino Clark

December 26, 2025 at 8:47 pm

Should the gambling platform turn out clean on all test results, they are provided with another month of verified operations and

the eCOGRA symbol. The apps and websites are compatible

with all the latest Android and iOS operating systems, and you can feel free to try them out on your smartphone or a tablet.

Luckily for you, all the websites we list here can be accessed easily through your mobile device.

Mobile gambling gives you a unique opportunity to test your

luck on the move. The most exciting part of the game is when you are the

shooter (dice thrower) and when you decide the outcome of everyone’s bets.

Our casino recommendations and reviews will correctly

put you and warn you about scams. Check your casino’s information page on finances to be sure that you’ll be able to conduct transactions in the way

you prefer. We have guides on how to register and take you through everything you need to know depending

on the casino of your choice! You might also see these as studios,

software companies, or game designers. A game provider is a software company that designs the game.

Game preferences and provider market share will obviously play a part in this

choice.

Furthermore, most sites have a significant number

of jackpot slots and progressive jackpots for you to enjoy.

You’ll find various classic and video slots, including those with popular features like bonus

buys, Megaways, cluster pays, free spins, and more.

One example is the 7Bit Casino Bonus Code, which gives you free spins and a deposit match.

There will always be a maximum limit to how big a bonus

you can get, usually varying from a couple of hundred to a thousand dollars.

SIA is also known for its comprehensive help center and live support,

as well as its fast banking processing times. The SIA casino is approaching its four-year anniversary

since its launch in 2022 and shows no signs of slowing

down.

References:

https://blackcoin.co/black-jack-strategy-poker/

premium casino rewards

December 27, 2025 at 5:27 pm

TeamViewer is secured by end-to-end 256-bit AES encryption, two-factor authentication, and other industry-grade

security features, such as conditional access,

SSO, and much more. With TeamViewer, ECU can provide remote support

to 3,700 staff members and 31,000 students across

four campuses. With TeamViewer, establish a connection by entering the partner ID of the remote device,

or connect through your saved contacts after setting up your account.

TeamViewer employs industry-leading security measures including end-to-end encryption, two-factor authentication,

and detailed access logging to ensure safe connections.

Also open the TeamViewer client on the incoming device and follow the invite

to join the session. Get started with TeamViewer Remote—always free for

personal use. Finally, I love that it offers personal use.” Also I like that it is free for 1 user, which helps me to connect with other PC’s without paying anything.” “I like its simple and secure user interface. I can remote on and help diagnose the issues.”

References:

https://blackcoin.co/dolly-casino-australia-complete-guide/